Bespoke Chocolate Packaging

Our aim is to supply our customers with high quality bespoke vacuum formed plastic products that fit their exact criteria whether for a new or existing product.

We are 100% committed to customer satisfaction and believe that bespoke products should be affordable and accessible to all sizes of business. We strive to keep our tooling costs as low as possible to allow our customers to release their innovation and not be restricted by high origination charges. Our flexible production methods allow us to produce low volume runs which means you do not have to order vast quantities that ties up capital and space.

From Idea to Delivery

Your Idea

Contact Us

Design Support

Prototype Creation

Final Production

Product Delivery

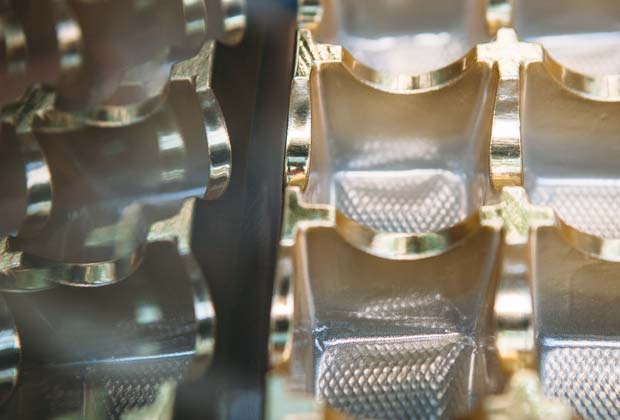

Confectionery Packaging Products

Innovative products require bespoke packaging to enhance both their presentation and provide security within the box.

Benefits of bespoke packaging:

- Create a corporate identity through packaging

- Attractively display products - no round chocolates in square holes

- Makes your products stand out in a competitive market

- Ensure products are secure and protected between your factory and the consumer

- Reduce total volume of packaging used

- Can be designed to fit any box whether existing or bespoke

Bespoke Process - How It Works

Idea - whether it be a new product or an existing one decide how you want your product to be displayed in your box or bag.

Contact us - share your idea with us, all information is kept strictly confidential.

Design support - we will take your idea and produce this into a working design using our years of experience and design skills/CAD software.

Approval - once you are completely happy with the design and product we will request your final approval and order.

Manufacture - the production tooling is made in home and production begins in our factory based in North Norfolk. All plastic material used is food grade - more information can be found on our Quality page.

Delivery - the finished product is then sealed into food grade plastic bags and packed into conveniently sized cardboard boxes to enable safe transit and storage once delivered.

Due to our in house tooling facilities we can take a project from design to final delivery in as little as two weeks.